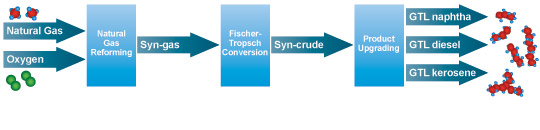

WHAT IS GTL - THE TECHNOLOGY

At the core of OLTIN YO'L GTL's technology is the Sasol Slurry Phase Distillate Process™ (SPD Process). This is a three stage process. In the first stage, natural gas is combined with oxygen to form a syngas. This syngas is then subjected to a Fischer-Tropsch conversion to produce a waxy syncrude. In the final stage, this syncrude is cracked down to produce the final products.

The three main products are diesel, kerosene and naphtha.

GTL diesel

With almost zero sulphur, GTL diesel is a high performance, low emissions product.

It can be used in existing diesel engines, either in a neat form or as a blendstock.

GTL diesel reduces some pollutants by up to 70% compared to standard crude-derived diesel and its cleaner and more complete combustion means less build up of deposits in the engine. This reduces engine wear, extends engine life and increases the interval between lubricant replacement.

GTL diesel can also be blended with standard crude-derived diesel, immediately improving the overall quality of the fuel without the need for costly refinery refits.

GTL kerosene

The world wants cleaner air travel and GTL kerosene offers airline operators a safe and cost-effective way to reduce emissions.

The GTL kerosene from OLTIN YO'L GTL will make Uzbekistan one of the few producers of the most advanced aviation fuel in the world.

Synthetic fuel is already a feature of aviation but GTL has the potential to surpass anything so far achieved in terms of performance and emissions. Aviation is yet another high value and enduring global market in which to realise the premium potential of GTL products.

GTL naphtha

GTL naphtha is a best in class product.

Highly paraffinic, GTL naphtha has virtually no aromatics or sulphur and negligible metallic contaminants. Light paraffinic naphthas are the most efficient liquid feedstocks for ethylene cracking and ethylene is one of the basic building blocks of the petrochemical industry; the precursor of widely used plastics such as polyethylene, polystyrene and other derivatives.

GTL naphtha paraffin content is typically 98 per cent, which is considerably higher than the 65 to 75 per cent of typical open-spec naphtha. A further advantage of GTL naphtha is the low coking/fouling rate for furnace tubes during cracking.

Demonstrably cleanerGTL delivers higher performance with lower emissions. |

|